- 30. January 2025

Demo-Video #1

Demonstration of a high resistance to chemicals in solvent-containing bonds

Demo-Video #1

Demonstration of a high resistance to chemicals in solvent-containing bonds

Demo-Video #2

Adhesion of heated bitumen welding sheet onto Kerdyn™ Green FR

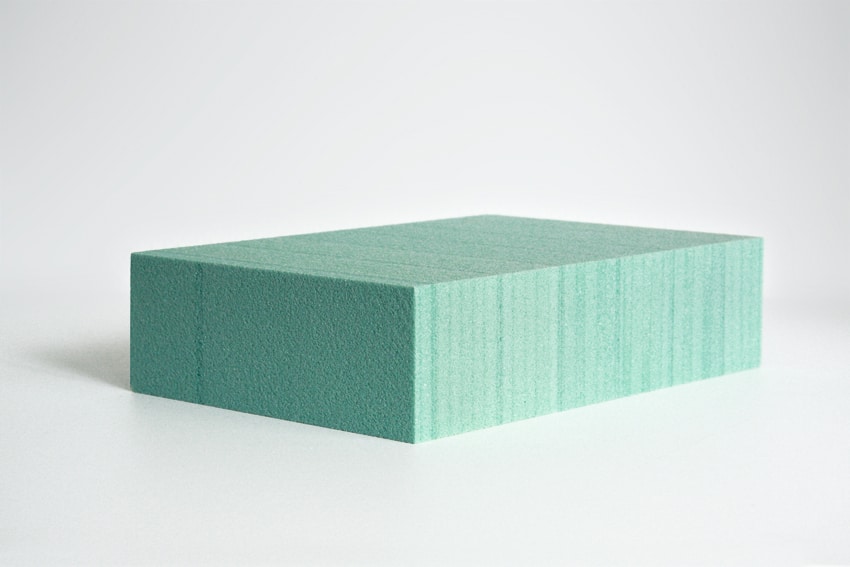

Kerdyn™ Green FR – a versatile working material

> Good mechanical properties (pressure and shear properties)

> Broad process compatibility due to high temperature and chemical resistance

> Recyclable polymer

> Optimal insulation properties

> Light-weight and cost-efficient composite structure

> Minimal water absorption

> Broad density spectrum

| Raw density | Kerdyn 80: 80 kg/m³ Kerdyn 115: 115 kg/m³ Kerdyn 180: 180 kg/m³ |

| Pressure resistance | Kerdyn 80: 1 N/mm² Kerdyn 115: 1,5 N/mm² Kerdyn 180: 3,2 N/mm² |

| Thermal conductivity | Kerdyn 80: 0,0270 W/mK Kerdyn 115: 0,0332 W/mK Kerdyn 180: 0,0403 W/mK |

| Board/panel size | 1005 x 2440 mm 1250 x 2440mm |

| Board thickness | 5 - 120 mm |

| Construction material class | B2 (DIN 4102) |

| Base material | PET-Recyclat |

Outstanding water resistance: an outstanding property that allows for diverse application opportunities.

Low thermal conductivity, high pressure resistance, and breathability: properties that create new perspectives.

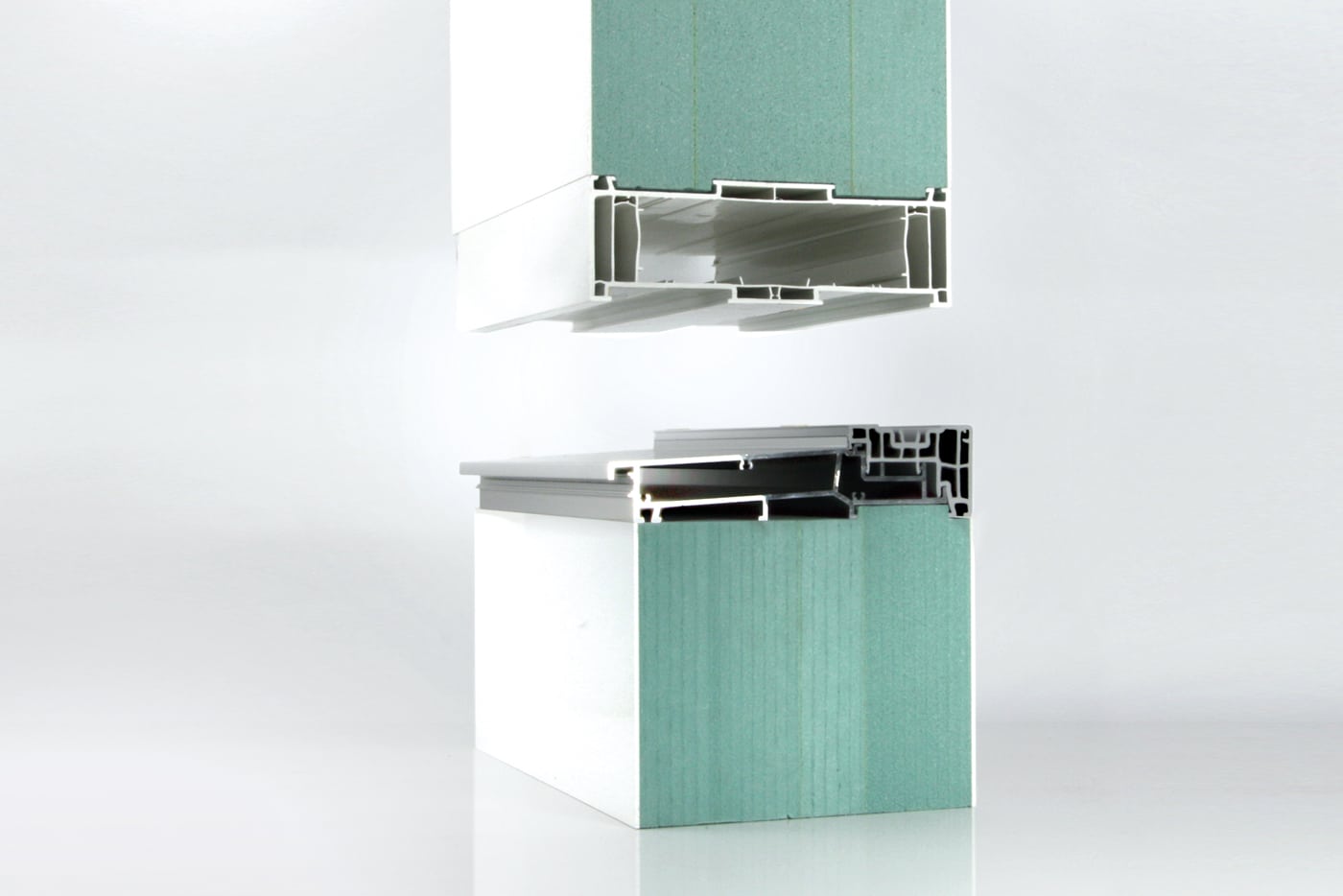

To produce Kerdyn® Green FR, PET granulate from the recycling process (drink bottles) is molten in an extruder and mixed with various additives and a propellant. This material is then extruded in an endless cord made up of many small “strings”.

After the extrusion tool, the strings unite into a raw board.

After a cooling period, the raw board is cut to a length of approx. 1300 mm and formatted quadrilaterally.

The thickness of the board is thereby reduced to approx. 45 mm.

In the next process, the raw boards undergo heating and are then welded into a block layer by layer.

After reaching its maximum size, the block is formatted six-sidedly to the size of 1005 x 1250 x 2400 mm.

The required boards are cut from this block.

This sophisticated process is selected to transfer the high mechanical properties parallel to the direction of extrusion into the board surface.

Please use our inquiry form

for all your questions and interests.

Our team will contact you

as soon as possible.