- 30. January 2025

FDKtherm

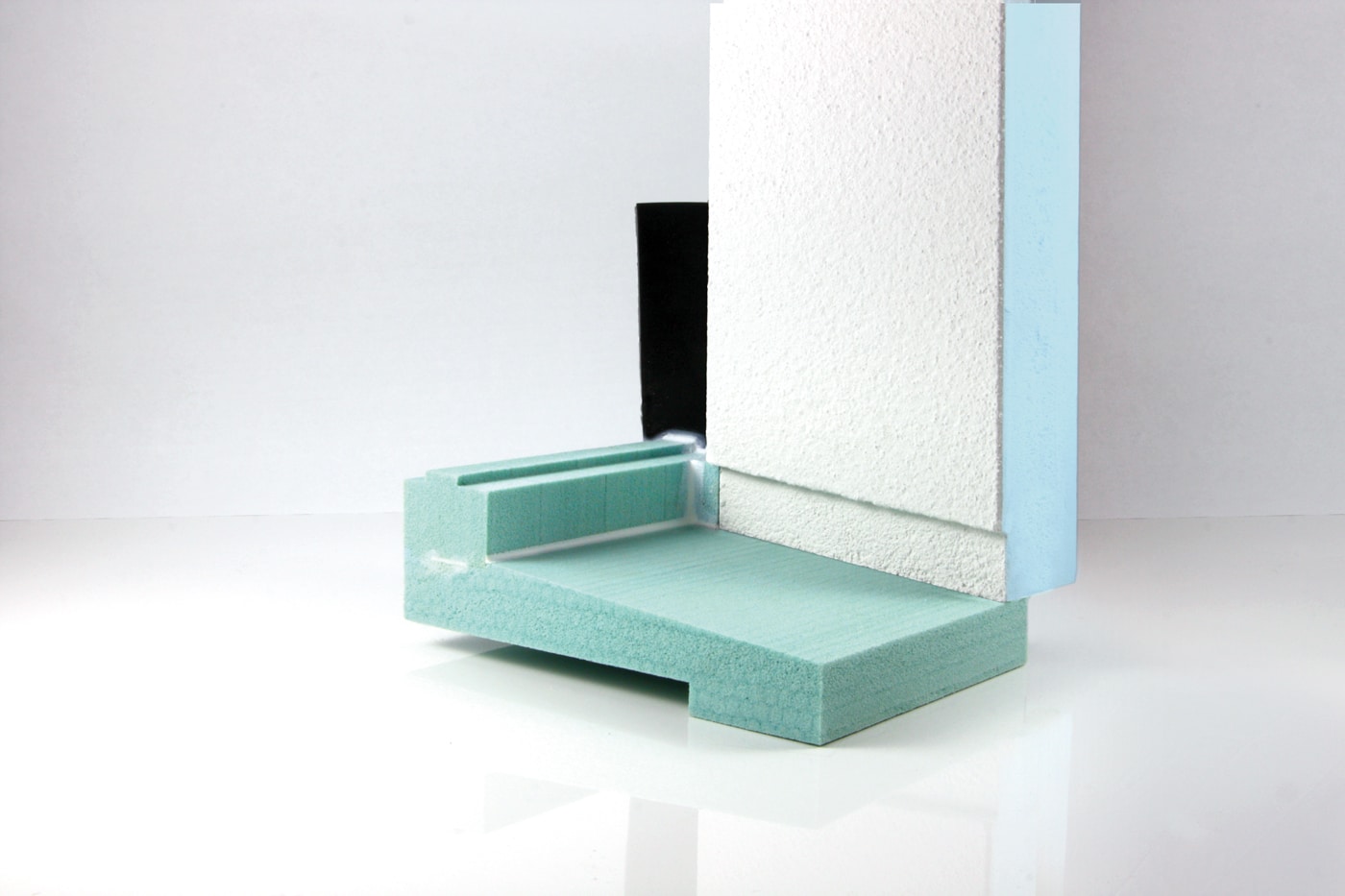

Windowsill Insulating Wedge and Sealing Wedge

FDKtherm Insulating Wedge and Sealing Wedge - THE PROVEN WINDOW INSTALLATION SOLUTION FOR ANY CONSTRUCTION PROJECT

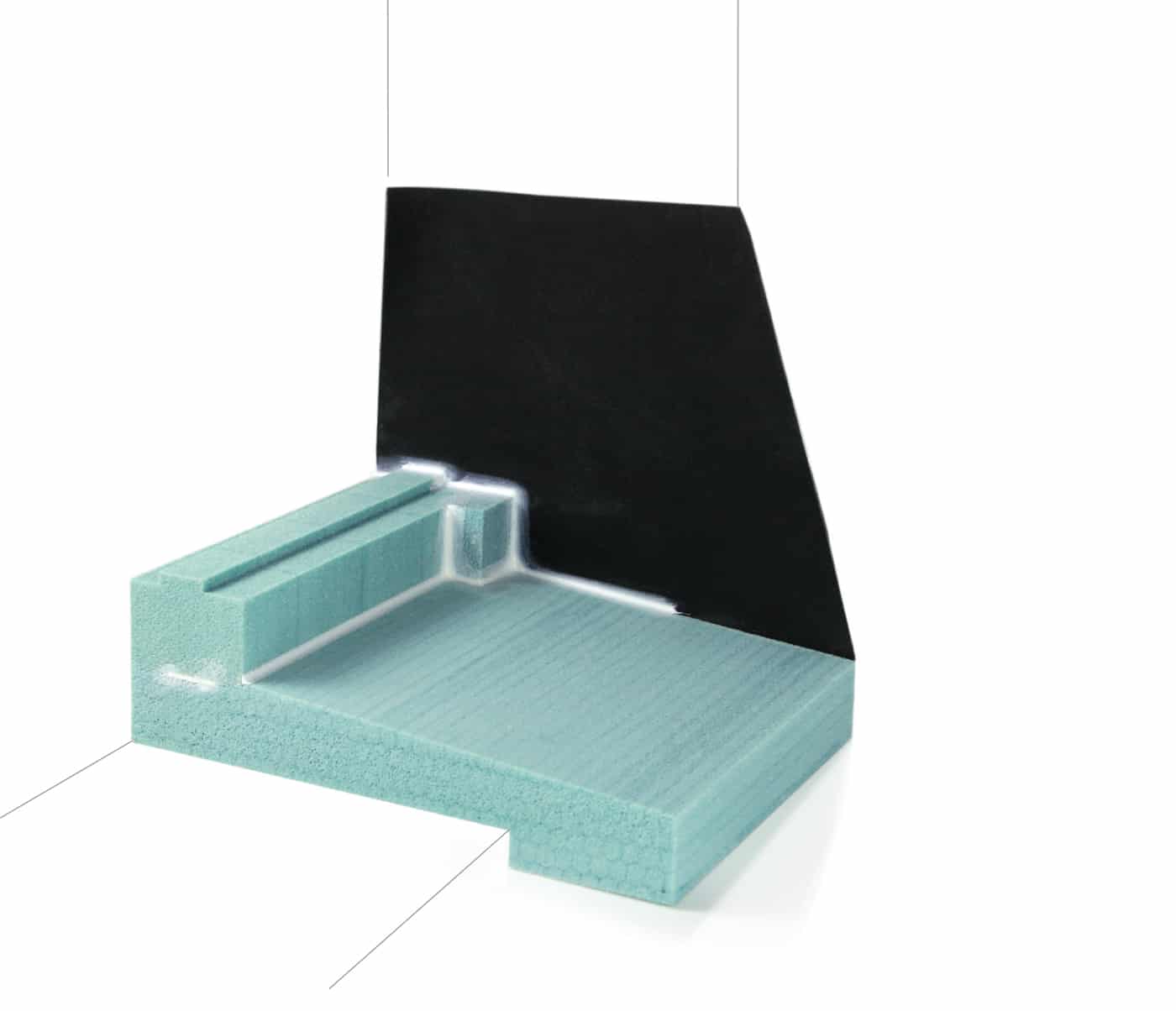

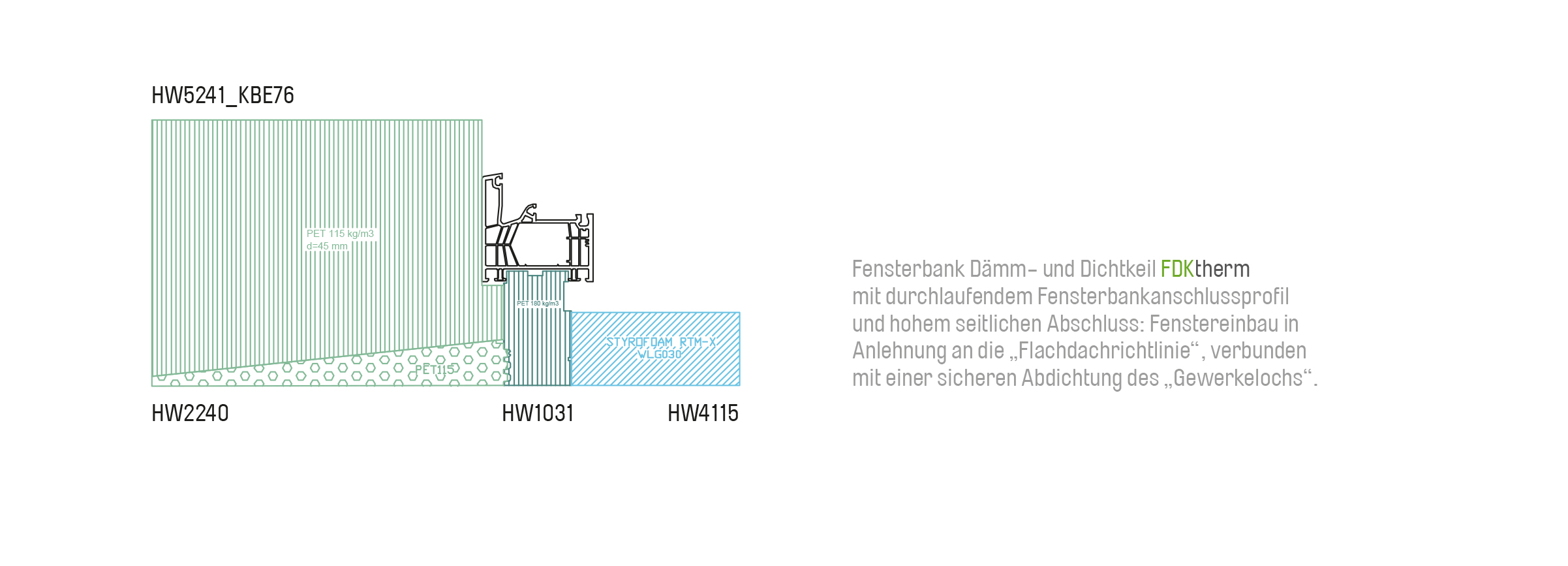

With our insulating wedge and sealing wedge, in combination with various lateral end caps and windowsill connection profiles specific to the trim frame, and adhesion with the hybrid adhesive vowafix one, you get a second water-bearing layer.

Insulating Wedge and Sealing Wedge FDKtherm made of Kerdyn™ Green FR

Water leakage into wall construction is prevented through special material selection – regardless of whether the wall is constructed of masonry, cement, or wood.

Sealing of the interface gap is significantly simplified through the lateral end caps. Additionally, correct insulation below the window sill that considerably reduces condensation development is achieved.

The insulating and sealing wedges are particularly applicable for windowsills made of stone or those that do not have edging rated for driving rain.

The insulating and sealing wedges can, depending on request, be made of Kerdyn™ Green FR or Phonotherm® 200. For normal loads, wedges made of Kerdyn® Green FST are sufficient. For very high loads, wedges made of Phonotherm® 200 may be better suited.

FDKtherm at a glance

100 % Waterproof

The optimal second water-bearing layer below the windowsill

Universal

Applicable for all types of windows and windowsills

Safe

Flawless and fast window installation without film sealant

Stable

Windowsills you can walk on available

Conforming to guidelines and standards

Lateral window sealing in accordance with flat roof guideline and DIN 18195

Expandable

Drip edge profile available

Tested

In accordance with ift-guideline MO-01/1 incl. climate cycle according to EOTA-ETAG 004

Combinable

Modular system with reveal panel LPtherm

One principle - two product versions

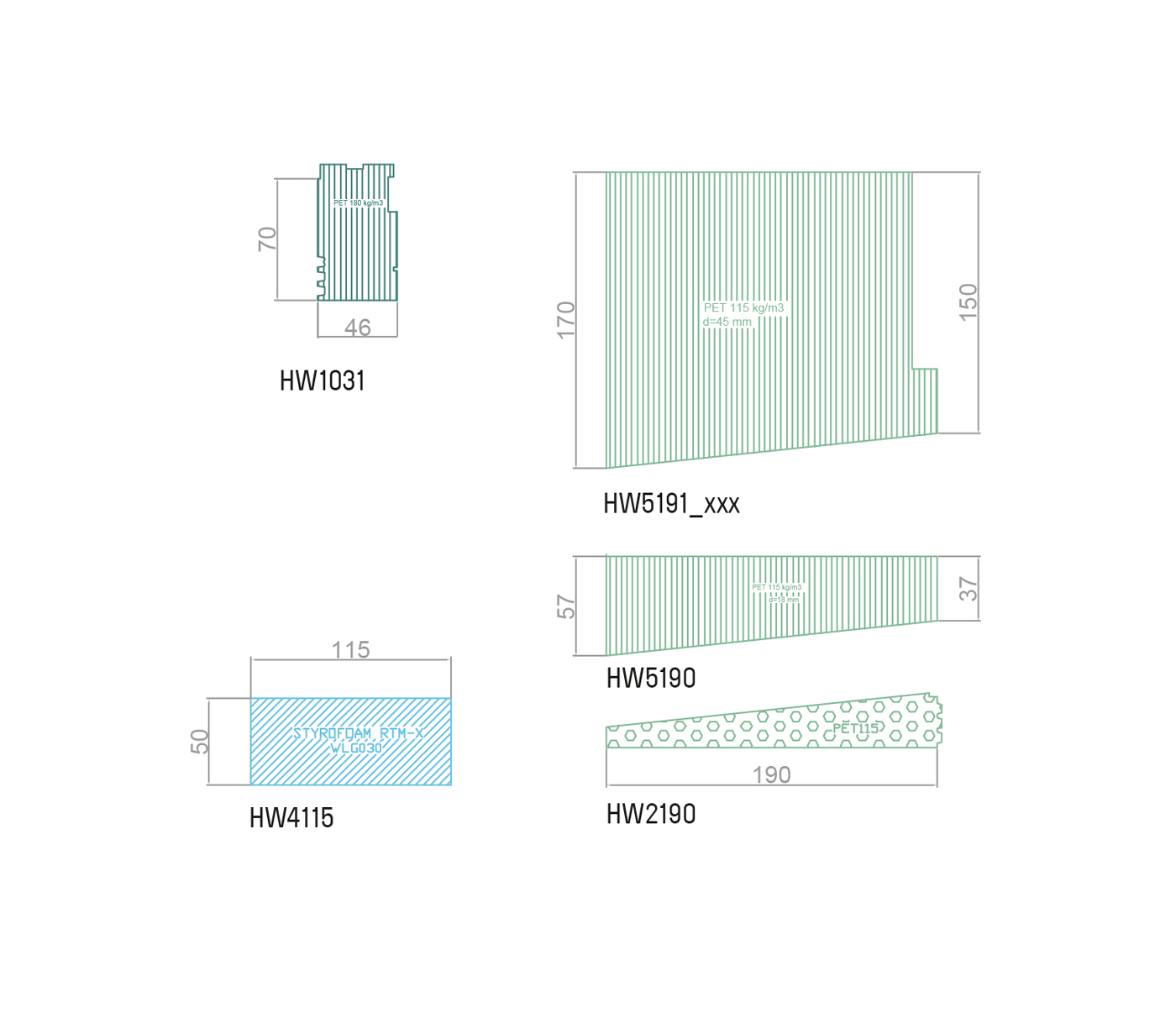

Depending on construction or processing situation, various requirements for an insulating and sealing wedge system may arise.

1 / FDKtherm as modular system

For window installation at the construction site or for smaller carpentry shops, the modular solution provides great flexibility with safe window transport to the installation site.

Other benefits

> In stock for all common window types

> Can be modified with regular woodworking machinery

> Available in small quantities

> Standard delivery length: 2400 mm

Insulating and sealing wedge as flexible, modular system

2/ FDKtherm as complete system

For standard window installation at a facility and consistently the same wall structure, we can develop a customized, prefabricated complete system that provides an even faster and smoother window installation.

Other benefits

> Customized system solution

> In mass production

> Optional delivery on agency basis

When developing a system solution, we support you in selecting optimum geometries and materials in reference to your technical and economic requirements.

Installation version especially for manufacturers of prefabricated homes made of timber frame construction or other building manufacturers with frequently recurring wall structures.

We provide comprehensive support in aligning the interfaces of our system with EWIS systems.

We organize and supervise desired testing in cooperation with the manufacturer of the EWIS or with independent testing institutes upon request.

Combination with our LPtherm reveal panels - the perfect installation solution

Truly safe and optimally-insulated window installation is achieved through our proven product pair: our FDKtherm insulating and sealing wedge as second water-bearing layer, combined with our pre-coated

LPtherm reveal panels – a clean and safe detail solution.

The time-saving and safe product combination: FDKtherm and LPtherm

High stability of the sub-windowsill

By using Phonotherm® 200 or Kerdyn™ Green FR, the FDKtherm sub-windowsill attains great stability that, on the one hand, protects against damage during installation, and, on the other, allows for glued windowsills to be walked on during their use.

Safe to walk on for maintenance or cleaning work

Element that reaches to the floor with exchangeable windowsill and

LPtherm reveal panel

The insulating wedge significantly optimizes the process of isotherms

Due to the low thermal conductivity of the materials used, optimal insulation below the windowsill is achieved. Depending on the installation situation, the insulating and sealing wedge runs underneath the windowsill connection profile into the building, or the wedge is attached to the windowsill connection profile.

The installation height of the system is 60 – 70 mm.

When selecting a wedge, the following factors should be considered: the position of the window in the wall construction, the distance of the outside edge of the window to the outermost insulation layer, and the position and dimensions of an existing roller shutter case.

Windowsill insulating wedge and sealing wedge in a wall of timber frame construction.

Installation steps for an insulating wedge and sealing wedge at the construction project:

FDKtherm AT A GLANCE

| Material | Phonotherm®200 |

| Dimensions | H 200mm L 400mm W 150mm |

| PSI value | 0.04 |

| Compatible with module | Yes |

| Application | Prefabricated homes, sunrooms/winter gardens |